Train III: Functional

June 2020

|

|

Train Specs:

1:35 scale Track Gauge: 26mm Length: 160mm Width: 44.5mm Height: 54mm Number of components: 410

Design Time: 25h Print Time: 30h Assembly Time: 15h Printer: Creality CR-10 Nozzle Diameter: 0.2mm |

How functionality was accomplished:

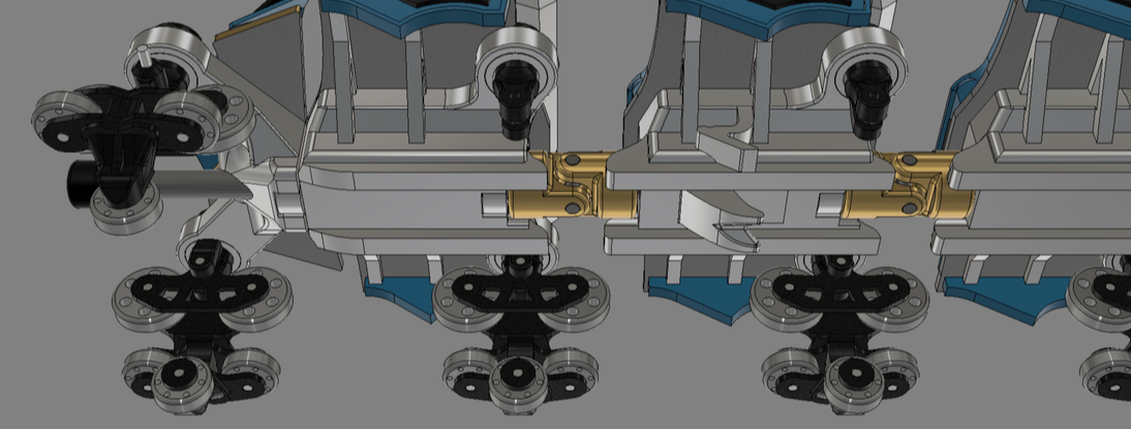

- Improved bogie design which reduced rolling friction by using printed wheels and better suited, low friction 3mm OD bearings

- Added bearings within spars to allow bogies to yaw smoothly, yet remain rigid with respect to the spine

- Reconfigured hitches between cars to use bearings and U-joints, which strengthened the connection and increased maneuverability

- Expanded spine width to allow for addition of masses and accommodate three across seating

|

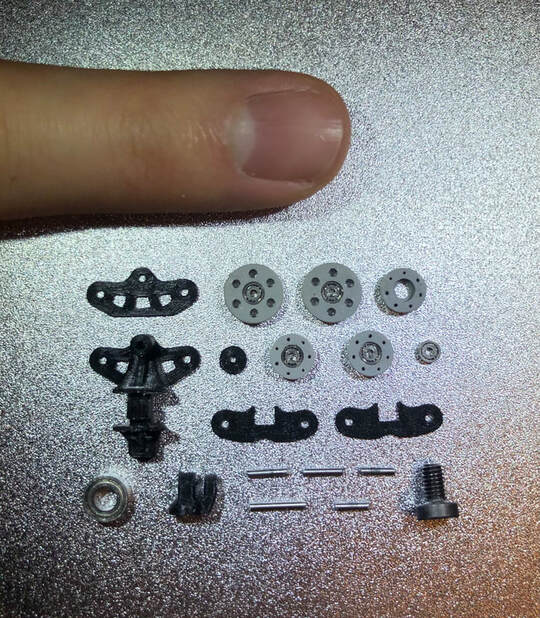

Each bogie is made up of 23 components, 11 of which are 3D printed. 6 bearings allow the bogie to function exactly as a full scale wheel assembly, including all the degrees of freedom necessary for free movement along a rail. The tedious assembly for each bogie had to be done 10 times, resulting in around 7 hours of labor.

|

A view of the underside of the train gives a better look at the construction of the hitch and bogie assemblies.

|

Fully assembled bogies attached to the vehicle spine

|

Finishing elements such as the chassis baseplate, seats, and restraints were built and added to the spine to complete the train.

|

|

After a few hundred cycles around the track, wear marks on the wheels began to form.

The train's performance began to deteriorate as the bogies' yaw axis weakened over repetitive forces subjected by the layout. A stronger bogie configuration would consequently be used in the following trains to eliminate this issue.

For a look at this train in action, check out Launch via the link below:

|

|