Train II: Second Iteration

February 2020

|

|

Train Specs:

1:35 scale Track Gauge: 26mm Length: 170mm Width: 42mm Height: 55mm Number of components: 261

Design Time: 30h Print Time: 40h Assembly Time: 20h Printer: Creality CR-10 Nozzle Diameter: 0.2mm |

The next step:

- Vastly improved train's overall appearance, detail, and complexity when compared to the first attempt

- Refined printing process by beginning to specifically design components with FDM 3D printing in mind

- Took another step in the direction of functionality by optimizing bogie design and experimenting with a new hitch configuration

|

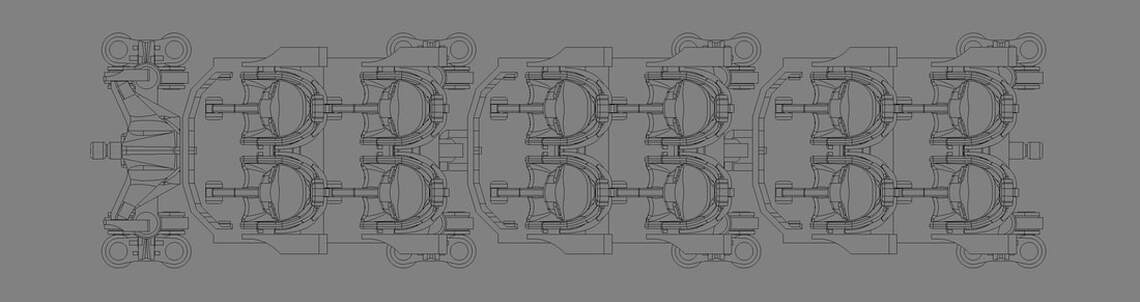

Bogie V2:

Bogie V2, as well as the rest of the train, were printed entirely with a 0.2mm nozzle as opposed to the Proof of Concept's 0.4mm. Tighter tolerances and thinner features were able to be used as a result, which greatly improved the overall design's fit and strength. To work against FDM's layer line issue, guide wheel brackets were independently printed flat and inserted into the bogie spine.

Due to the scale and printing with only millimeters of material, it was difficult to balance realism and structural integrity.

|

|

|

|

This train took around 3 months to design, print, paint, and assemble.

It was largely inspired by Premier Rides' Sky Rocket II trains as well as Mack Rides' Launch and Hyper Coaster trains.

Everything was modeled in Fusion 360 and sliced for printing in Cura.

|

|

|

Instead of hand painting, the majority of components were spray painted to achieve a more consistent finish as well as save a considerable amount of time.

|

|

|

The updated hitch uses a M2 tie rod end. It's fastened through its ball with a bent rod that is press fit into the following spine. The tie rod itself is then glued and press fit into the spine of the previous car.

The zero car design remained unchanged from the first train and simply rolls on a 3mm bearing press fit into the first car's spine.

|