Train I: Proof of Concept

August 2019

|

|

Train Specs:

1:35 scale Track Gauge: 26mm Length: 160mm Width: 42.5mm Height: 44mm Number of components: 243

Design Time: 15h Print Time: 20h Assembly Time: 10h Printer: Creality CR-10 Nozzle Diameter: 0.4mm |

An initial attempt:

- To keep a full 3D printed layout's footprint minimal, a small track gauge was chosen resulting in numerous design challenges

- Although they have bearings for wheels, the bogies aren't technically fully functional as they can't yaw

- Using a standard 4mm nozzle limited the detail that was able to be achieved

|

|

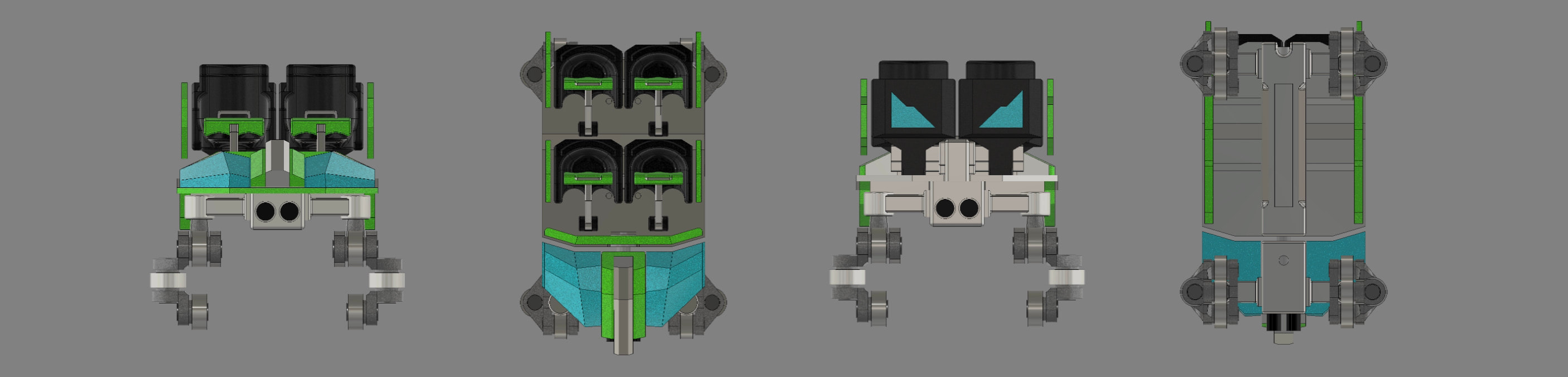

First-Gen Bogies:

When the first test parts were printed, it was surprising just how small 1:35 scale was. Certain aspects of how the bogies functioned had to be modified and tolerances had to be tweaked to get them to a semi-workable state. The 0.4mm nozzle was able to print the simple geometry of the original design, but it was clear that it would not be able to handle more complex shapes, so a 0.2mm nozzle would be used for all future trains.

3mm steel rod was used as axles for the bearings, which resulted in extremely minimal layer perimeters in an attempt to keep the overall size of the bogie down. The weak walls often broke during assembly resulting in the train's inability to be trusted on a functional layout.

|

|

After painting, the process for assembling the train began with installing hitch hardware into the spine (3mm rod, bearing, and U-joint) and attaching the spars that would hold the bogies. The baseplate and restraints came next, followed by the seat support bars. Seats and side panels were added lastly to each car. Finally, all three cars were connected via the U-joints and the zero car "theming" was added.

|

While being the least detailed and most unrealistic of all projects attempted, this train was extremely important as a jumping off point and proof of concept that a functional ride vehicle could be built at this scale.